All about Avoid equipment breakdown with Lubrication Maintenance

- industrial machine maintenance, Industrial maintenance training, Lubricants maintenance

Minimal Emphasis on Lubrication will result in Far more Ridiculously priced Malfunction. Hence, the growing importance of Lubrication maintenance.

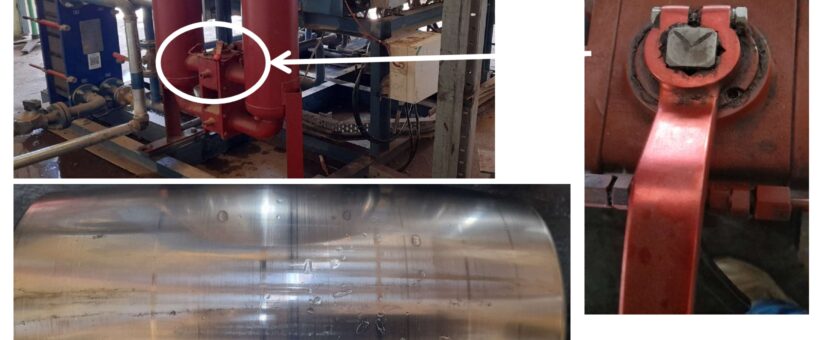

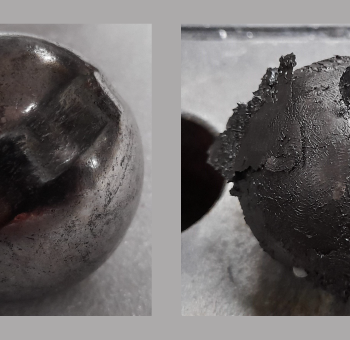

A slewing bearing used in an industrial application cracked on the outer ring mounting hole bolt area, with contamination and lubrication playing a role.

Avoiding lubrication maintenance & a haphazard approach to your lubrication programmer will allow contamination to enter, resulting in failure.

Even to this day, lubrication maintenance tasks have been given a very basic layman with the grease bucket, a grease gun & finally a cotton waste.

The job is to go to go at the machine and pump grease until the old black grease does not come out and later wipe off the grease nipple and extra grease with the cotton waste.

There is no awareness in terms of the Quantity, Frequency, Quality, Grease Type etc..

This is the ground reality in many organizations and change need to usher in with the process of knowledge sharing, Awareness Creation etc. with the involvement of the maintenance department. That is how things are going to change, a larger emphasis on lubrication maintenance.

Contact us for more info and know about our services. We also provide training on machine maintenance section .

0 Comments