Root Cause Failure Analysis of a Pitch bearing of a Windmill- Preventive and Predictive Maintenance

- bearing maintenance, Bearing Training Course, preventive and predictive maintenance

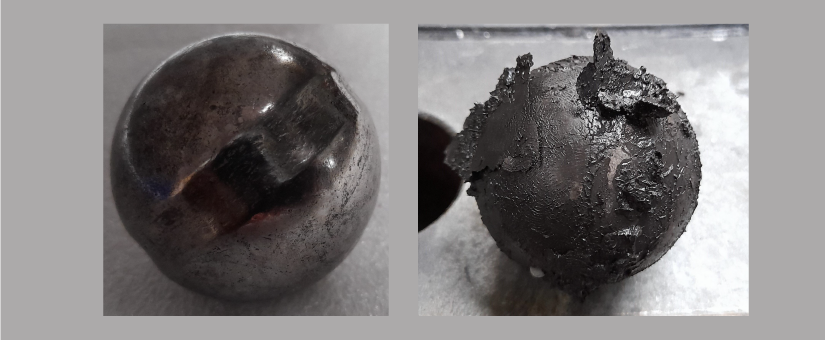

Pitch bearing of a windmill when dismantled for conducting the root cause failure analysis, found the balls in this condition. Grease analysis done and found <1% OIL separation after 24 hrs.

As this is under warranty, OEM says we are greasing the bearings as per schedule and no sign of failure recorded until the end user decided to replace the bearing for different reasons.

Should we always believe what OEM says? or Ask for proper condition monitoring reports and process followed?

In this case timely grease analysis could have saved this bearing as vibration monitoring is not possible.

0 Comments