Clean & Smarter not Dirty & Harder

- 3m Abrasives

Grease failures cause more bearing failures than oil failures, accounting for more than 60% of all bearing failures. Whenever the bearings are replaced in the housing, the housing is mostly fully packed with grease without leaving empty space and starts operating the bearing after the housing end covers are sealed. Immediately after a few minutes […]

Read More

Surface-Initiated Failure or Breakdown due to lack of lube management :

- lube management, lubrication maintenance

Have you ever seen a surface-initiated failure or breakdown due to the lack of lube management? This is common in gears, bearings, and other rotating equipment. The crack begins at the surface of the part and propagates into the metal due to the ignorance of lube management of the equipment. This is caused by stresses […]

Read More

All about Avoid equipment breakdown with Lubrication Maintenance

- industrial machine maintenance, Industrial maintenance training, Lubricants maintenance

Minimal Emphasis on Lubrication will result in Far more Ridiculously priced Malfunction. Hence, the growing importance of Lubrication maintenance. A slewing bearing used in an industrial application cracked on the outer ring mounting hole bolt area, with contamination and lubrication playing a role. Avoiding lubrication maintenance & a haphazard approach to your lubrication programmer will […]

Read More

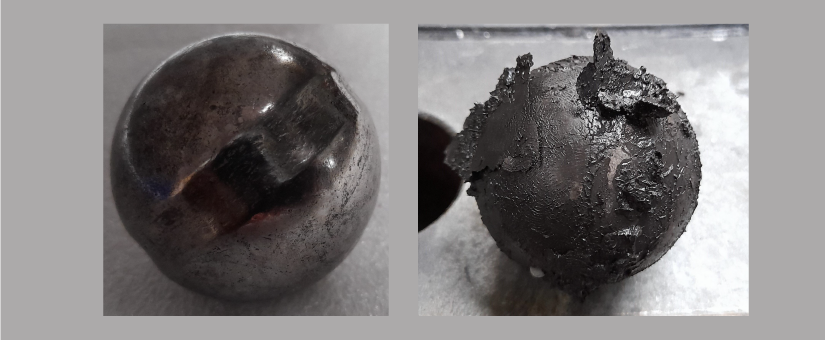

Root Cause Failure Analysis of a Pitch bearing of a Windmill- Preventive and Predictive Maintenance

- bearing maintenance, Bearing Training Course, preventive and predictive maintenance

Pitch bearing of a windmill when dismantled for conducting the root cause failure analysis, found the balls in this condition. Grease analysis done and found <1% OIL separation after 24 hrs. As this is under warranty, OEM says we are greasing the bearings as per schedule and no sign of failure recorded until the end […]

Read More

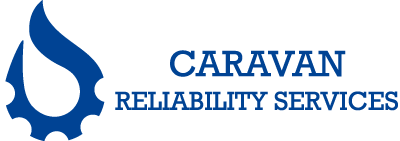

Case Study about CRB Misaligned in a Gearbox- Bearing Failure Analysis

- bearing condition monitoring, Bearing Failure Analysis, machine bearing

Caravan Reliabilty team facing an real issue related to Bearing Failure. A Customer using gearbox in his paper plant application was informed about a bearing problem while routine vibration analysis by a 3rd party agency and could not specifically identify the real issue. Later the same customer approached us to identify what was wrong in […]

Read More